Date : 05/03/2014 (Wednesday)

Title : Etching process on the copper board

according to the PCB layout

This is the result of PCB Layout design using

Dip-Trace software. Design is ready to be printed using Toner Printer (carbon

ink). The next step is to attach PCB layout on the copper board.

Clothes iron will be used to iron the PCB

design to attach on the surface of copper board.

After attaching the PCB design on to the

copper board. It will be placed into the etching acid. This process takes about

20 minutes to remove the remaining copper that is not needed.

- The simplest method, used for small-scale

production and often by hobbyists, is immersion etching, in which the board is

submerged in etching solution such as ferric chloride. Compared with methods

used for mass production, the etching time is long. Heat and agitation can be

applied to the bath to speed the etching rate. In bubble etching, air is passed

through the etchant bath to agitate the solution and speed up etching

- Chemical etching is usually done with

ammonium persulfate or ferric chloride. For my project, Ferric Chloride

Anhydrous powder is used for etching process.

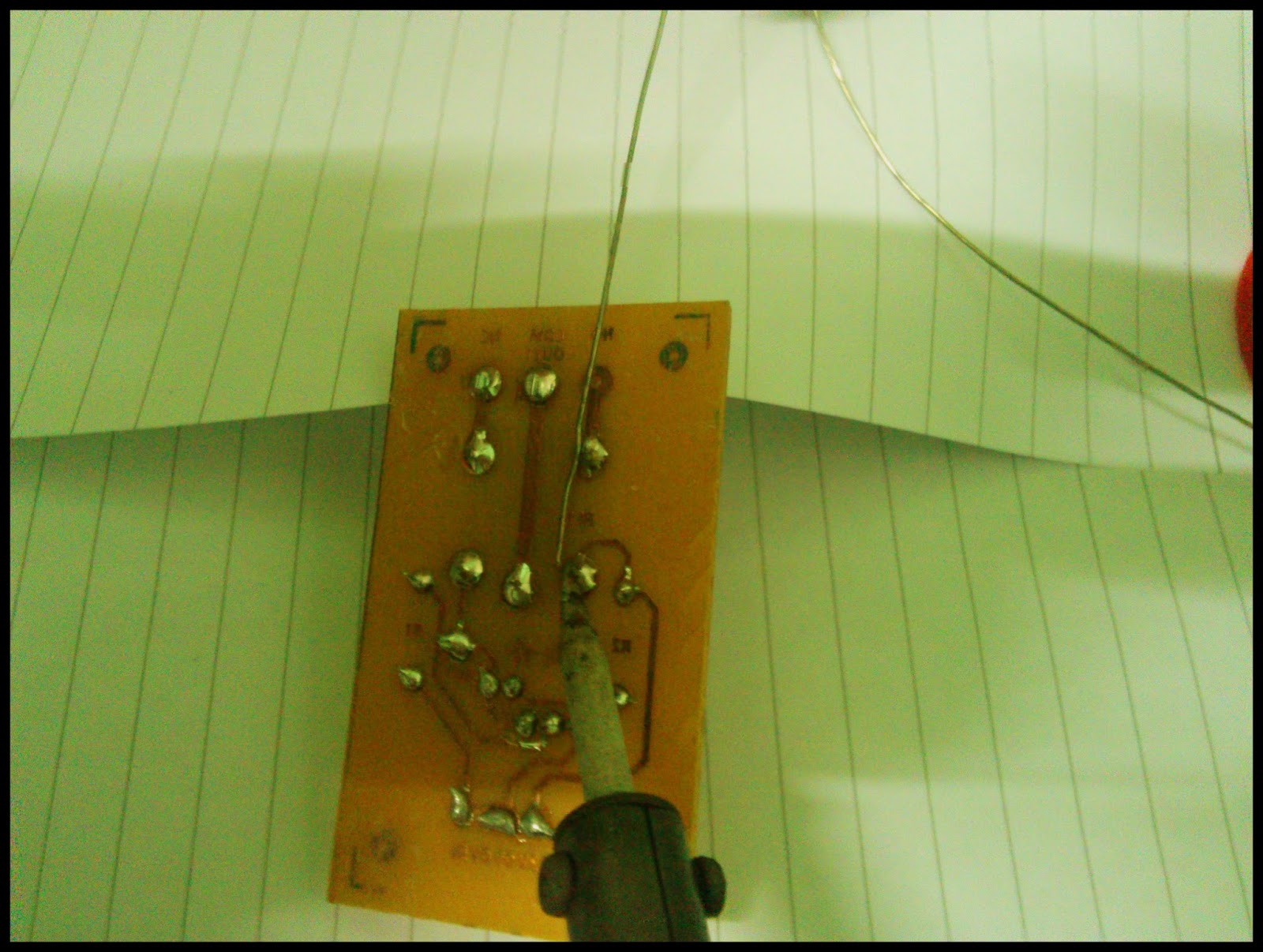

- The results of the etching process. Copper

is not needed will be eroded, only copper that covered by carbon ink will

remain on the board and form a circuit.